The Pulsar PTG1022H parts diagram is a detailed guide for understanding and maintaining your walk-behind string trimmer. It provides a clear visual breakdown of all components, ensuring proper maintenance and repair. This essential tool helps users identify parts, troubleshoot issues, and extend the lifespan of their equipment.

1.1 Overview of the Pulsar PTG1022H Walk Behind String Trimmer

The Pulsar PTG1022H is a robust walk-behind string trimmer designed for efficient cutting. Equipped with a 173cc OHV engine by Ducar, it offers reliable power for light-to-moderate brush cutting. Its 22-inch cutting width ensures precision trimming near fences and tight spaces. Easy to assemble and start, this trimmer is ideal for maintaining large outdoor spaces with minimal effort and maximum results.

1.2 Importance of the Parts Diagram for Maintenance and Repair

The parts diagram is crucial for maintaining and repairing the Pulsar PTG1022H effectively. It provides a visual guide to identify components, ensuring accurate repairs and preventing delays. By referencing the diagram, users can locate sensors, valve seats, and other parts quickly, reducing errors and extending the trimmer’s lifespan. It also helps in cross-referencing part numbers with the manual for precise replacements and troubleshooting.

Key Components of the Pulsar PTG1022H

The Pulsar PTG1022H features a 173cc OHV engine, 22-inch cutting width, and an easy-assembly design. These components ensure efficient performance for light-to-moderate trimming tasks.

2.1 Engine Specifications: 173cc OHV Engine by Ducar

The Pulsar PTG1022H is powered by a 173cc OHV engine manufactured by Ducar, known for reliability and efficiency. This engine features a recoil start system, offering smooth performance and easy starting. Designed for durability, it supports the trimmer’s operation with consistent power delivery, making it suitable for light to moderate trimming tasks around your property.

2.2 Cutting System: 22-Inch Cutting Width

The Pulsar PTG1022H features a 22-inch cutting width, enhancing efficiency for larger areas. This design allows close trimming to fences and edges, making it versatile for various tasks. The cutting system is robust, ensuring consistent performance and reliability. It’s a key feature that contributes to the trimmer’s effectiveness in handling light to moderate brush with ease.

2.3 Assembly and Startup Process

The Pulsar PTG1022H is designed for easy assembly and startup, making it user-friendly. The process is straightforward, requiring minimal tools and effort. Once assembled, the trimmer starts effortlessly, ensuring quick operation. This feature makes it ideal for users seeking a hassle-free experience while maintaining efficiency in trimming tasks.

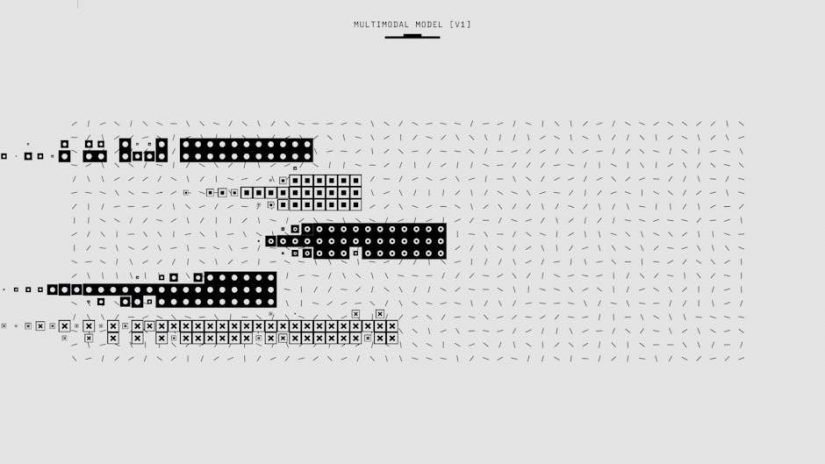

Detailed Parts Breakdown

The Pulsar PTG1022H parts diagram provides a comprehensive overview of components, including the sensor, auxiliary valve seat, diaphragm bushing, and main valve seat washer, ensuring clarity and ease of identification.

3.1 Individual Parts List: Sensor, Auxiliary Valve Seat, Diaphragm Bushing, and More

The Pulsar PTG1022H parts diagram lists essential components like the sensor, auxiliary valve seat holder, auxiliay valve seat, diaphragm bushing, main valve seat washer, and slip connection. These parts are crucial for the trimmer’s operation, ensuring proper fuel flow, carburetion, and engine performance. Referencing this list helps in identifying and ordering replacement parts efficiently.

3.2 Main Valve Seat Washer and Slip Connection Details

The main valve seat washer (part #130) and slip connection are critical components in the Pulsar PTG1022H parts diagram. The main valve seat washer ensures proper sealing and fuel flow, while the slip connection provides flexibility in the fuel line setup. These details are highlighted in the engine parts manual, pages 21 and 22, aiding in precise identification and replacement during maintenance or repair.

How to Use the Parts Diagram Effectively

Referencing the Pulsar PTG1022H parts diagram enhances maintenance and repair efficiency. It allows users to accurately identify components, cross-reference part numbers, and locate replacements quickly.

4.1 Identifying Parts for Repair or Replacement

Use the Pulsar PTG1022H parts diagram to locate and identify components needing repair or replacement. Cross-reference part numbers with the manual to ensure accuracy. This process helps maintain performance and extends the trimmer’s lifespan by addressing issues promptly.

4.2 Cross-Referencing Part Numbers with the Manual

Always cross-reference part numbers from the parts diagram with the manual to ensure accuracy. This step prevents mismatches and ensures the correct components are ordered or replaced. Aligning part numbers with the manual guarantees proper fitment and functionality, extending the trimmer’s lifespan and maintaining optimal performance.

Maintenance and Troubleshooting Tips

Regularly inspect and maintain your Pulsar PTG1022H to ensure optimal performance. Use the parts diagram to identify and replace worn components, addressing issues promptly for smooth operation.

5.1 Regular Maintenance to Ensure Optimal Performance

Regular maintenance is crucial for the Pulsar PTG1022H. Check the engine oil, clean or replace air filters, and inspect the cutting system. Lubricate moving parts and ensure proper tension on belts and cables. Refer to the parts diagram for accurate part numbers and locations, ensuring all components function correctly for reliable operation and extended equipment lifespan.

5.2 Common Issues and Solutions Using the Parts Diagram

Common issues with the Pulsar PTG1022H include engine misfires and cutting system malfunctions. Use the parts diagram to identify faulty components and replace them. For example, a clogged carburetor or worn spark plug can cause engine issues. Referencing the diagram helps locate these parts quickly, ensuring effective repairs and minimizing downtime. Regular inspection and maintenance can prevent these problems from arising;

Engine Parts Diagram and Breakdown

The Pulsar PTG1022H features a 173cc OHV engine by Ducar, with detailed parts breakdown on pages 21 and 22 of the manual for easy reference and maintenance.

6.1 Ducar Engine Parts Manual: Pages 21 and 22

Pages 21 and 22 of the Ducar engine manual provide a detailed breakdown of the 173cc OHV engine components. These pages list essential parts like the sensor (part 6), auxiliary valve seat holder (part 8), auxiliary valve seat (part 16), diaphragm bushing (part 25R), main valve seat washer (part 130), and slip connection. Referencing these pages ensures accurate identification and maintenance of engine components.

6.2 Understanding the Engine’s Role in the Trimmer’s Operation

The 173cc OHV engine by Ducar is the heart of the Pulsar PTG1022H, powering its cutting system and mobility. It ensures efficient performance for light-to-moderate brush trimming. Proper engine maintenance, guided by the parts diagram, is crucial for optimal operation. The engine’s reliability directly impacts the trimmer’s effectiveness, making it essential to understand and maintain its components regularly.

Assembly and Reassembly Guide

The Pulsar PTG1022H is designed for easy assembly and reassembly, ensuring efficient operation. A detailed guide provides step-by-step instructions for proper setup and maintenance.

7.1 Step-by-Step Assembly Instructions

Assembling the Pulsar PTG1022H involves attaching the handle, trimmer head, and other components. Start by mounting the engine, ensuring all bolts are securely tightened. Next, align the handle with the main frame and fasten it using the provided hardware. Finally, install the cutting head, making sure it is properly seated and balanced. Refer to the parts diagram for precise guidance during assembly.

7.2 Reassembly Tips to Avoid Common Mistakes

When reassembling the Pulsar PTG1022H, ensure all parts are properly aligned and securely fastened. Refer to the parts diagram to confirm correct placement. Avoid over-tightening bolts, as this may damage threads. Double-check that moving components, such as the cutting head, are free from obstruction. Lubricate essential joints to ensure smooth operation and prevent premature wear. Always follow the manual’s torque specifications for optimal performance.

Safety Precautions and Best Practices

Always wear protective gear like gloves and safety glasses. Ensure the area is clear before starting the trimmer. Properly handle tools to avoid accidents.

8.1 Safe Handling of Parts and Tools

Always wear protective gear like gloves and safety glasses when handling parts. Ensure tools are stored securely to prevent accidents. Handle sharp or heavy components with care, and keep loose clothing tied back. Properly secure the trimmer before performing maintenance to avoid unintended startup. Regularly inspect tools for damage to maintain safety.

8.2 Operating the Trimmer Safely

Always wear protective gear, including gloves, safety glasses, and sturdy footwear. Clear the area of debris before use. Avoid operating near bystanders or pets. Maintain a firm grip and steady pace. Never reach near moving parts while the engine is running. Ensure the trimmer is on level ground and properly assembled. Follow the manufacturer’s guidelines for safe operation.

Refer to the Pulsar PTG1022H manual and parts diagram PDF for detailed maintenance and repair guidance. Visit the official Pulsar website for downloadable resources and support.

9.1 Where to Download the Pulsar PTG1022H Manual and Parts Diagram

The Pulsar PTG1022H manual and parts diagram PDF can be downloaded from the official Pulsar website or trusted platforms like ManualsLib. Visit the Pulsar support page, enter your model number, and access the resources. Ensure you download from verified sources to avoid incorrect or incomplete information. These documents are essential for proper maintenance and repair of your trimmer.

9.2 Final Thoughts on the Importance of Proper Maintenance

Regular maintenance is crucial for the longevity and performance of your Pulsar PTG1022H trimmer. By following the parts diagram and manual, you can identify and replace worn components, ensuring optimal functionality. Proper care not only enhances efficiency but also prevents costly repairs. Consistent upkeep guarantees your trimmer remains reliable for years, maintaining your outdoor spaces effortlessly and effectively.